With China's accession to the WTO, all these shortcomings and weaknesses will improve. This is because after the WTO accession, the market is gradually internationalized, and the powder metallurgy market will be further expanded. At the same time, with the entry of foreign capital and technology, the level of powder metallurgy and related technologies will also be improved and developed. Now the current situation of the powder metallurgy gear market analysis. The application range of gear molds mainly includes three aspects: plastic gear mold, powder metallurgy gear mold and precision forged bevel gear mold. Among them, the demand for molds for powder metallurgy gears is the largest. At present, the development of China's gear molds is still in its infancy, most of which are small and medium-sized powder metallurgy gears that are processed using molds. Due to deformation and shrinkage during powder metallurgy gear processing, the accuracy of shrinkage after shrinkage is currently domestic. Research is still not deep, which has become one of the most important reasons for restricting the development of powder metallurgy gear molds.

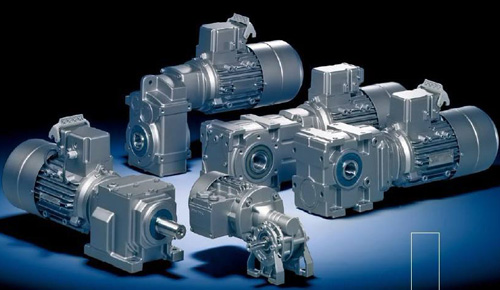

Although powder metallurgy gears are difficult to count separately in powder metallurgy parts, the proportion of powder metallurgy gears in automobiles and motorcycles is much larger than that of powder metallurgy parts in other fields, both by weight and by part. Therefore, from the rise of the proportion of automobiles and motorcycles in the whole powder metallurgy parts, it can be seen that the powder metallurgy gears are in a rapid development position in the whole powder metallurgy parts. 2016-2021 China's powder metallurgy gear industry market supply and demand prospects depth research report shows that the gear does not seem to be eye-catching, but it is an important part of industrial equipment. China's gear industry is basically composed of three parts, namely industrial gears, vehicle gears and gear equipment. Among them, the market share of vehicle gears reaches 60%; industrial gears are composed of industrial general purpose, special purpose and special gears, with market share of 18%, 12% and 8% respectively; gear equipment accounts for 2% of market share. During the fifteenth period, the total output value of the gear industry increased from 25 billion yuan to 50 billion yuan, the average growth rate was close to 20%, doubled in five years, ranked fourth in the world, and the sales scale exceeded 100 million enterprises. The industry concentration was obvious. improve. At present, among the five major categories of products in the gear industry, hundreds of series, and thousands of products, there are a large number of products with international advanced level. In 2006, the annual output value of the gear industry was 59 billion yuan, of which the proportion of vehicle gears was as high as 2/3. The driving force of the automobile industry is an important support for the development of gear molds.

The gear consumption is very large, and each car has more than 20 gears of various sizes. Most of the automobile gears are made of gear steel 20CRMNTI. Only a small number of high-class passenger car transmission gears are made of stainless steel, so the gear steel is growing synchronously with automobiles, ships and construction machinery. In addition, the export of mechanical and electrical products drives the demand for gears. In recent years, the export of mechanical and electrical products has increased by more than 30% every year, and the consumption of gears has increased by more than 25%. The market for special and special gear transmissions is also very large, such as non-circular gears, powder metallurgy gears, small modulus gears, etc. The demand for gear steel is also not small.

From this point of view, due to the continued release of the effective demand of the terminal during the year, the support gear steel market is running smoothly and the price is firmer.

With the maturity of the gear industry and the downstream development of the gear industry, such as the automotive industry, the output value of China's gear industry in 2006-2010 will be close to 100 billion yuan, ranking in the world rankings, and from 2011 to 2015, striving for the world. The ranking is guaranteed to compete for one.

The domestic gear mold industry can be described as mixed. The good news is that the domestic gear mold production has a certain foundation, and the rapid development of powder metallurgy gear will also bring greater market space to the gear mold. Worry is that compared with the advanced production level of foreign gear molds, there is still a certain gap in the level of domestic production of gear molds, and in the gear industry, especially the plastic gear industry, the development is big, the country is not sensitive enough to respond to market changes. It is a bit difficult for supporting research to keep up with market demand.